How to Extend the Life of Your Heavy-Duty Truck Parts

Heavy-duty truck parts are built to work hard—but even the toughest components won’t last if they’re neglected. With rising parts costs, supply chain delays, and tighter margins, extending the life of your truck parts isn’t just smart maintenance—it’s smart business.

Whether you manage a fleet, run a repair shop, or own your own rig, the right habits can significantly reduce downtime, prevent premature failures, and protect your bottom line.

Here’s how to get the most out of your heavy-duty truck parts.

1. Follow a Proactive Maintenance Schedule

Preventive maintenance is the single biggest factor in part longevity. Many component failures don’t happen suddenly—they’re the result of small issues left unaddressed.

Best practices:

- Stick to manufacturer-recommended service intervals

- Inspect critical components during routine PMs

- Address minor wear before it becomes major damage

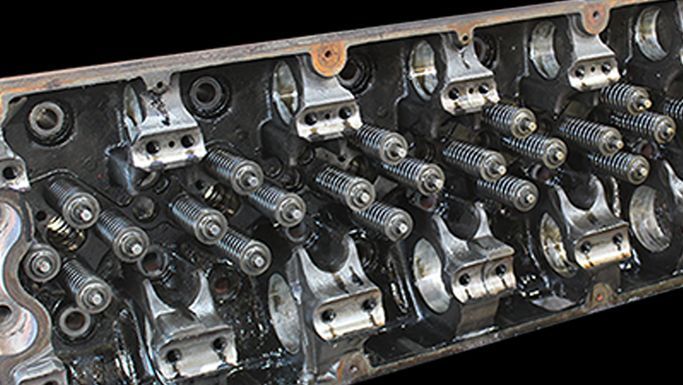

Regular inspections of engines, turbos, transmissions, and cooling systems can add years to component life and prevent costly roadside breakdowns.

2. Use Quality Replacement Parts

Not all parts are created equal. Cheap or poorly manufactured components often fail early, leading to repeat repairs and more downtime.

When replacing parts:

- Choose reputable aftermarket or remanufactured components

- Verify proper fitment and compatibility

- Look for parts with warranties or guarantees

High-quality remanufactured parts can deliver OEM-level performance at a lower cost—without sacrificing reliability.

3. Keep Fluids Clean and at Proper Levels

Fluids are the lifeblood of heavy-duty components. Dirty, degraded, or low fluids dramatically shorten part life.

Key areas to monitor:

- Engine oil

- Coolant systems

- Transmission fluid

- Differential and axle lubricants

Regular fluid analysis and timely changes help prevent overheating, corrosion, and internal wear—especially in high-mileage or severe-duty applications.

4. Don’t Ignore Early Warning Signs

Unusual noises, vibrations, warning lights, or performance changes are rarely “nothing.” Ignoring them often turns a small fix into a major repair.

Pay attention to:

- Changes in boost pressure or exhaust smoke

- Hard shifts or slipping transmissions

- Overheating or coolant loss

- Oil consumption or contamination

Catching issues early can extend the usable life of parts and prevent collateral damage to surrounding components.

5. Store and Handle Parts Properly

For shops and fleets that stock parts, improper storage can reduce lifespan before a part is even installed.

Storage tips:

- Keep parts clean, dry, and protected from moisture

- Seal openings on engines, turbos, and fuel components

- Label and rotate inventory to avoid long-term degradation

Proper handling ensures parts perform as intended when they’re finally put into service.

6. Match the Part to the Application

Installing the wrong part—even if it fits—can shorten its life dramatically. Duty cycle, load demands, and operating conditions all matter.

Before installing:

- Confirm the part meets the truck’s workload requirements

- Consider reman or upgraded components for high-stress applications

- Consult experienced parts suppliers or technicians when unsure

Using the right component for the job prevents overloading and premature failure.

7. Work With Knowledgeable Parts Partners

A trusted parts supplier can be just as important as a skilled technician. Experienced suppliers help you choose reliable components, avoid common pitfalls, and source alternatives when OEM parts are unavailable.

The right partner offers:

- Technical support and product knowledge

- Access to new, reman, and used parts

- Consistent availability and fast shipping

- Years of experience in the heavy-duty parts industry

Strong supplier relationships lead to better repairs—and longer-lasting results.

Summary

At River City Truck Parts, we understand that extending the life of your heavy-duty truck parts isn’t about cutting corners—it’s about making smarter decisions. With proactive maintenance, quality parts, and the right support, you can reduce downtime, control costs, and keep trucks on the road longer.

In an industry where time is money, part longevity makes all the difference. We are here to help, contact us to discover why we are a trusted partner committed to keeping trucks moving!